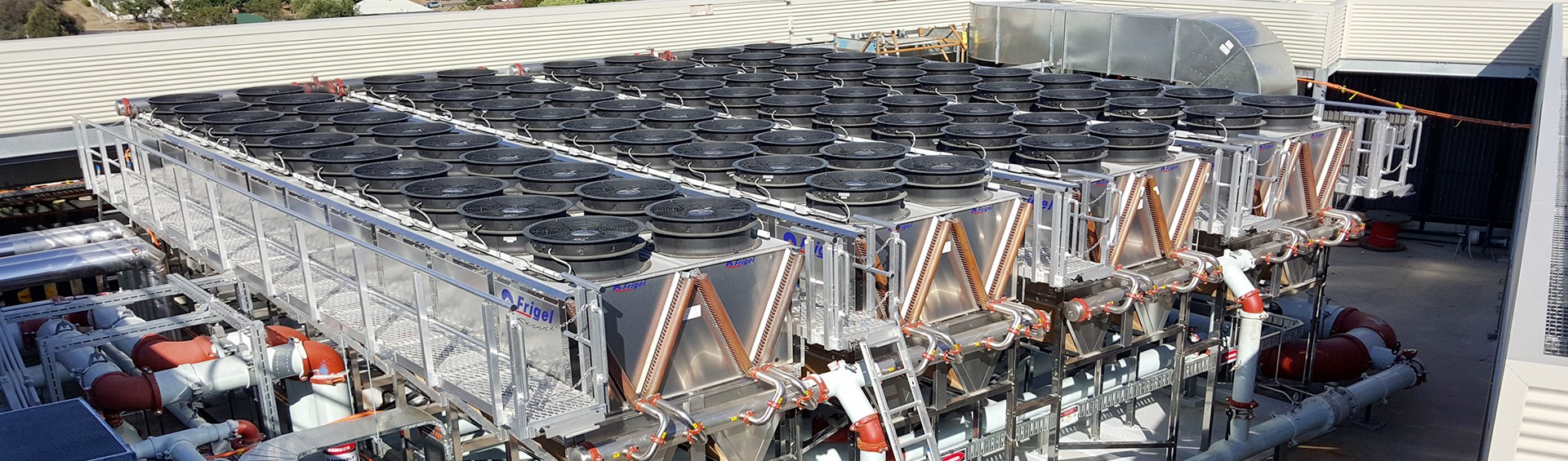

The replacement of the evaporative cooling tower

Adiabatic Cooling

Reduced operating costs and safeguard of water resources.

Every day, huge quantities of fresh water are consumed through the use of traditional evaporative systems for the heat dissipation of industrial processes (cooling towers). The increasing shortage of water resources, the difficulty in finding them and the constantly increasing costs are pushing the industry towards this new technology, able to save up to 95% of water: adiabatic cooling. This technology also provides greater efficiency in heat transfer, reduced maintenance and the total absence of polluting chemical agents.

Over 9,000 systems installed in each climate zone.

Discover our products

What is adiabatic cooling?

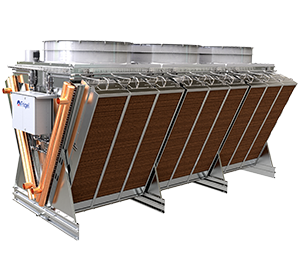

It is a water cooling system using closed circuit ambient air, which combines:

- Finned pack water-to-air heat exchanger (radiator)

- Axial fans for forced air convection

- An adiabatic system for air pre-cooling during hot weather

- A monitoring device for system management

How adiabatic coolers work?

Water consumption only if required

It has 2 working modes:

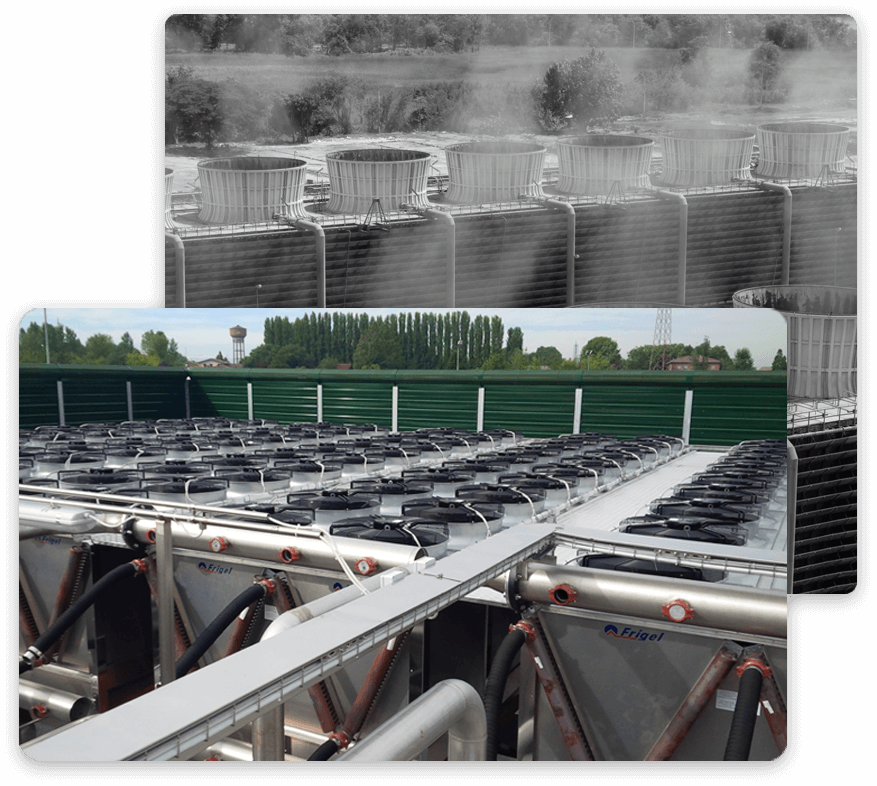

1. “Dry” Mode

During most of the year, the unit works as a conventional dry-cooler, with no water consumption and the heat transported by the water is dissipated in the ambient air by convection of the air forced by the fans.

2. “Adiabatic” Mode

During high ambient temperature periods and only when the dry mode is not sufficient to maintain the outlet water temperature within a pre-set maximum set point, the adiabatic mode is automatically activated. The high temperature ambient air, before entering the finned exchanger, passes through the “adiabatic chamber” (patented) where humidity is added and consequently it is pre-cooled. In this case, the control system continuously regulates the quantity of water evaporation, only when necessary, to maintain the desired set point.