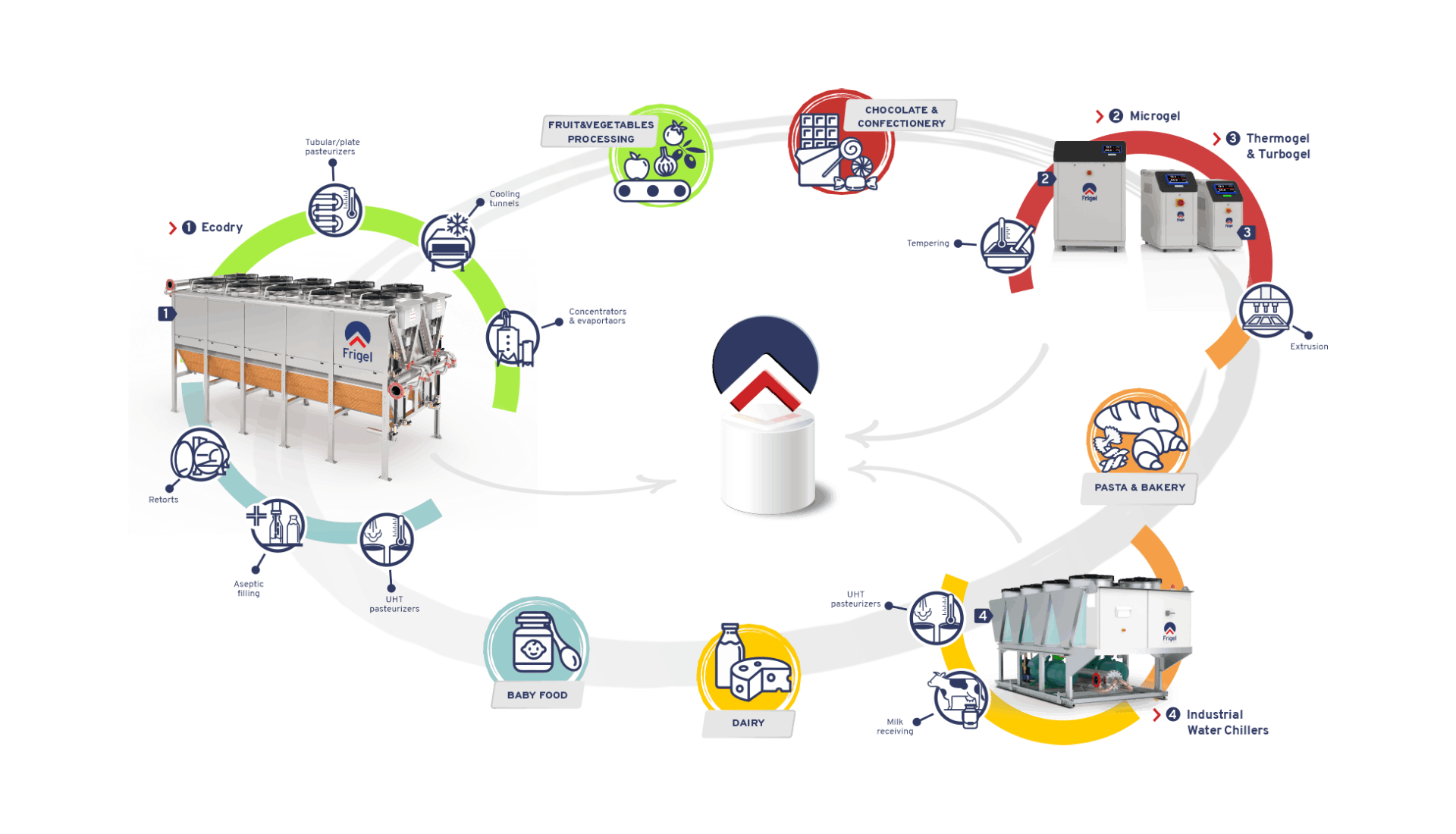

Process Cooling for FOOD

We design custom food processing chiller systems to meet operation’s specific needs. Our wide line of innovative solutions can be used for a variety of food processing applications, including: Cheese, Yogurt, Ice cream, Chocolate, Bakeries, Fruit, Vegetables, Confectionery, etc.

)and discover all the advantages of our solutions:

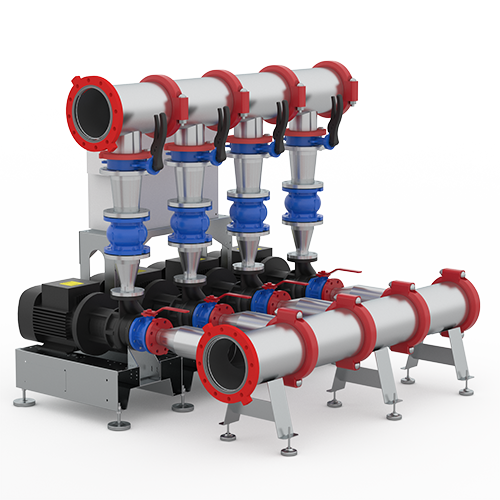

)and discover all the advantages of our solutions:Industrial Chiller

Air-cooled industrial refrigeration units

- High energy efficiency

- High reliability and easy maintenance

- Environmental sustainability

Machine Interactive Database

Supervision system for plant control and optimization

- Remote control of machines from everywhere

- Live data recording (all the operating parameters)

- Data stored locally, physically installed on-site

- Safe and encrypted Data transfer

Ecodry 3DK

Adiabatic Cooling System

- Operation guaranteed with minimum water consumption and maintenance even in extreme weather conditions, up to +50 °C (120 ˚F) ambient temperature

- Safe operation without glycol down to an ambient temperature of -40 °C (-40 ˚F)

- High energy savings of the fans in partial load operation

Ecodry 4DK

Adiabatic Cooling System

- Up to 15% less energy consumption

- Water saving up to 95%

- Safe operation without glycol down to an ambient temperature of -30 °C (-22 ˚F)

- Remote monitoring

- Improved COP up to 30%

Microgel Packaging RCP

High performance mold cooling unit

- Cooling synchronized with the process

- Cycle time reduction up to 30%

- High energy efficiency (pumps and compressors with inverter)

Microgel industrial Processes RVM

Water condensed refrigeration unit

- Temperature and cooling flow set point synchronized with the line

- Status of the cooling system synchronized with the line: ON, OFF, IDLE, CIP, etc.

- Can be used as a heat pump for energy recovery

Thermogel

Pressurized water Temperature Control Unit, designed for general plastics molding applications up to 140 °C/284 °F.

- Control of the mold temperature synchronized with the process

- High precision: +/- 0.1 °C (+/- 0.2 ˚F) of the set value

- High accessibility for easy maintenance

Thermogel 120

Pressurized water Temperature Control Unit, designed for general plastics molding applications up to 120C.

- Control of the mold temperature synchronized with the process

- High precision: +/- 0.1 °C (+/- 0.2 ˚F) of the set value

- High accessibility for easy maintenance

Download the brochure of the cooling system Food

Performance and sustainability without compromise

Reduced carbon footprint up to 50% less

Unbeatable efficiency, free-cooling and heat recovery opportunities.

Increased productivity

1. Maximum flexibility

There is no limitation for settings of coolant temperature and flow rate delivered to each process. The operator is able to record the cooling parameters that maximize the processing line speed for each specific product.

2. Perfect stability

Each unit assures precise temperature control and constant flow rate of coolant to each process with complete independence - avoiding interference from the demands of other processes.

3. Full automation and connectivity

Each cooling Unit is automatically operated by the processing line and is constantly communicating with it, reducing ramp-up times and any dead time during production stops, change of formats, change of product, etc.

4. High reliability

All Ecodry Sytem components are factory assembled and pre-tested before shipping. MultiStage units are typiclly designed with one back-up stage, all easily replaceable in case of failure.

Reduced operating costs

1. Energy savings up to 30%

• Maximum overall system efficiency (EER/COP) - Each refrigeration unit operates at a specific temperature, guaranteeing the highest level of efficiency for each refrigeration circuit for each process.

• Maximum operational efficiency of each unit (EER/COP) - Each process with a high temperature differential is associated with a MultiStage cascade refrigeration system equipped with compressors and pumps with inverters.

• Optional Free-Cooling - The refrigeration units integrate the automatic Free-Cooling function. Whenever the temperature required by the process is higher than the temperature provided by the central system, the refrigeration compressors are unloaded or stopped.

• Heat recovery option - The units can be used as heat pumps for water heating by recovering up to 100% of the heat taken from the refrigeration loads.

2. Water savings up to 95%

The Central Adiabatic Cooling system operates in dry mode without water consumption for almost the whole year, exploiting the ambient air to reject the heat coming from the processes. Only during extreme heat periods above 30 ˚C (86 ˚F) does the system uses a minimum amount of water in evaporative mode.

3. Maintenance and industrial security savings up to 90%

Refrigeration units require simple maintenance and they operate with harmless gases that do not require specific safety infrastructures. In addition, the central adiabatic system is a closed circuit requiring minimum maintenance.

Total modularity

1. Easily expandable at any time

The Ecodry System allows the installation of the exact capacity required at each stage of plant development.

2. Exact quantification of cooling costs by line and product

Each unit can measure and record the specific energy consumption for each product.

3. Total reliability

The extreme simplicity, reliability and redundancy of the components of the adiabatic cooling unit minimizes the possibility of plant shutdown due to failures of the cooling system, ensuring the continuity of production 24 hours a day.

Reduced carbon footprint up to 50% less

1. Intelligent electricity consumption

With minimal waste.

2. Maximum savings

Obtained thanks to automatic and independent Free-Cooling by process.

3. Possibility of reducing the consumption of natural gas

Thanks to the heat recovery of processes through heat pumps.

Almost no water footprint

Unlike traditional systems, this new heat dissipation technology minimizes water consumption caused by refrigeration systems that provide direct evaporation to reduce temperatures.

Lowest risks of emissions

1. Free of ammonia

Unlike traditional systems, the system ensures the total absence of ammonia.

2. Low GWP refrigerant

The system uses a refrigerant gas with the lowest GWP available to date.

3. Risk of losses and emissions reduced to a minimum

In each unit the refrigerant gas is divided into small separate circuits, minimizing the risk of emissions in the event of leaks or leaks.

4. No disposal of chemical additives

It does not require the disposal of chemical additives used for water treatment.

Other Solutions for Food

Discover our alternatives

High performance meets sustainability. The energy used by processes can make a difference for your costs.

Frigel has worked restless to provide you the right recipe.