A paradigm shift in the plastics industry

Ecodry System 4.0 Process-Synchronized Cooling

Frigel was the pioneer in the introduction of the Ecodry System in the plastic industry.

This technology has yielded excellent results for the industry and has been successfully validated in more than 8,000 installations worldwide.

Now, Frigel brings the Ecodry System to a higher level: the new approach is based on complete digital connectivity between the temperature control system and the process machine, aligning it with the future: the Industrial Revolution 4.0.

Performance and Sustainability

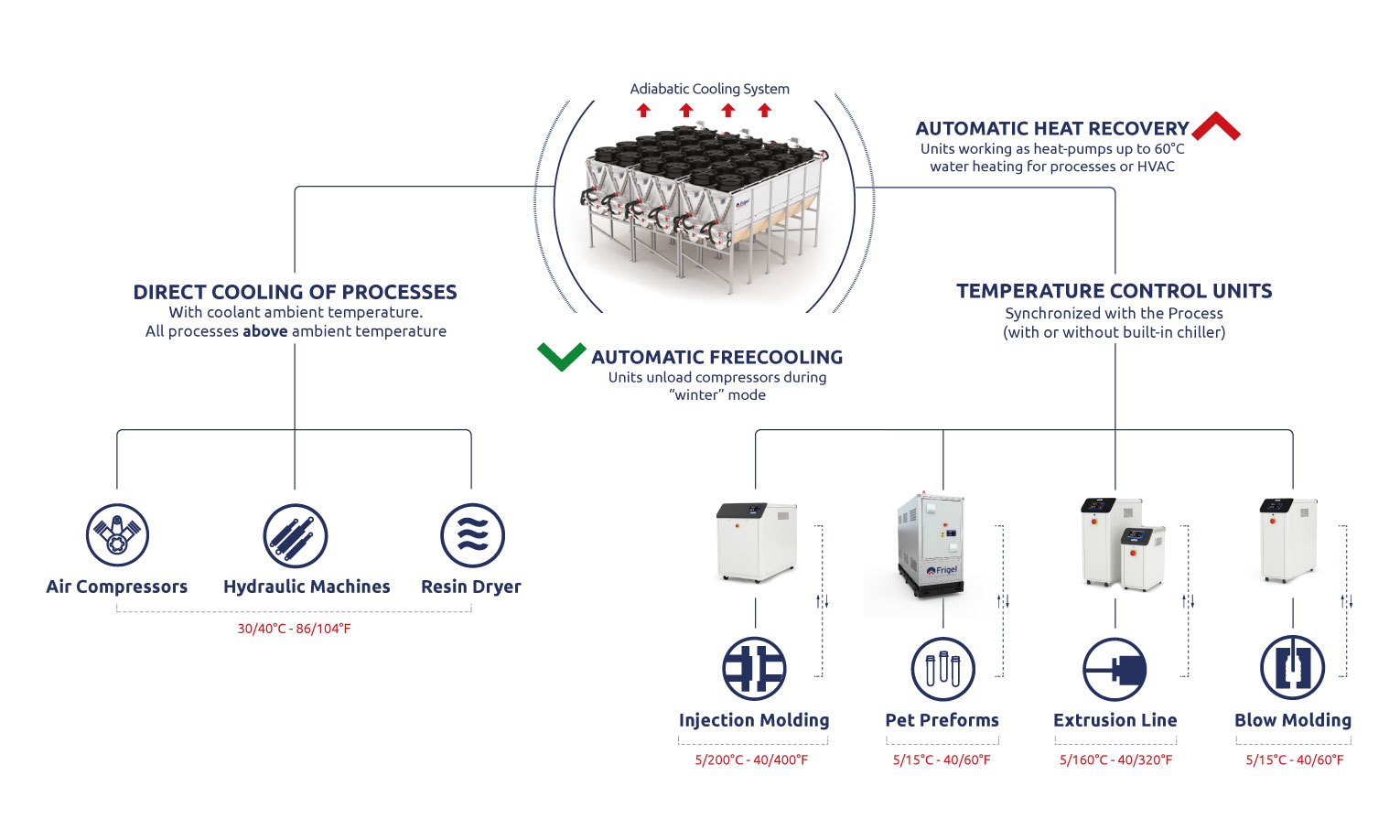

How does Ecodry System 4.0 work?

Integrated cooling solution for Plastic Industry

From high-complexity automotive components to ultra-fast thin-wall packaging, this new approach covers all the needs of temperature control in molding, blow molding and extrusion.

Full ranges from 5 to 200 °C (40 to 400 ˚F)

Temperature Control Units Synchronized with the Process

Designed to provide each mold with the required temperature with the proper flow, in the right place and, now, “at the right time”.

Unlike traditional systems, Ecodry System does not have a centralized chiller to provide process cooling.

Instead, it is served by a complete range of temperature control units that can have the built-in chiller (Microgel) or not (Thermogel and Turbogel), covering every specific application requirement from 5 to 200 °C (40 to 400 ˚F).

Digitally synchronized with the machines that automatically manage them, these units allow the processors to search for the best cooling parameters for each product, able to maximize quality and cycle time.

These parameters can be stored and then restored each time the line produces the same item.

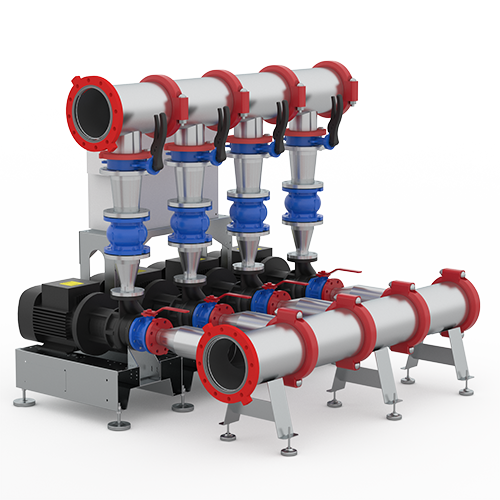

Ecodry

Central Adiabatic Cooling System

The Ecodry System is completed by units installed at each mold and connected to a central adiabatic cooling system positioned outside to expel the heat deriving from the processes.

This modular system - alternative to evaporative towers - consists of closed circuit coolers that can keep the cooling temperature even lower than the ambient temperature.

Furthermore, this centralized system can provide direct cooling to all other users that require water at a temperature higher than the ambient temperature, such as hydraulic machines, resin dehumidifiers, air compressors, water-cooled chillers, etc.

Ecodry System 4.0 for the Plastic Industry

Discover the new cooling technologies to achieve high standards of productivity and product quality in every field of application.

Automotive

Innovative solutions that cover all the application needs of high quality molded components for the automotive industry.

Learn more

Packaging

Cooling technologies designed to reduce cycle time in the molding and blowing of rigid containers and closures.

Learn more

Medical

Cooling systems designed for molded and extruded components, with high quality requirements for the medical sector.

Learn more

Technical Molding

High performance cooling and thermoregulation solutions for every application: molding, blowing and extrusion in general.

Learn more