Case Story Toyo Seikan Thailand

A new aseptic filling line cooling.

Frigel and Toyo Seikan continued their technical collaboration for subsequent projects. In 2022 and 2023, Frigel was again chosen as a partner for further cooling projects, for a new aseptic processing plant and for packaging plants (preform production).

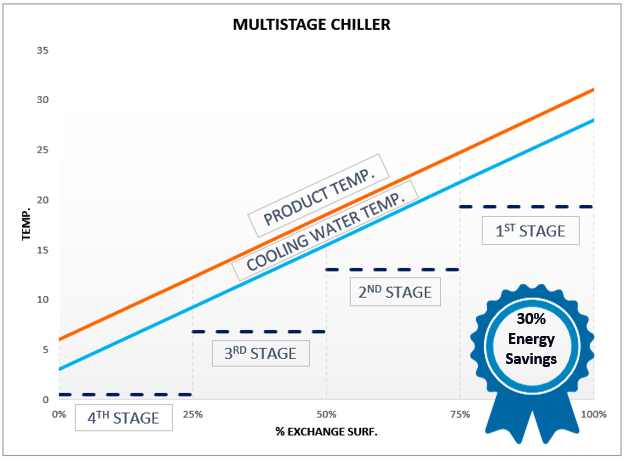

Toyo Seikan chose to expand the cooling capacity while at the same time benefiting of the new Frigel Multistage technology. Frigel Multistage technology is an ideal alternative to common chillers for all those processes where high temperature drops are present, such as foods and beverages production processes.

Objective

- Expansion of the chiller system

- System upgrade to Multistage technology by Frigel

- Remote monitoring and supervision system

The Multistage technology allows to “break down” very high temperature differentials into smaller steps (stages), which are performed by a series of cascaded chillers (the nr of stages is optimized depending on the process features).

Contrary to traditional solutions, this technology allows chillers (stages) to work at a higher average evaporation temperature and thus significantly increase their efficiency. Furthermore, the cooling water can ideally replicate the temperature drop of the product thereby reducing the required flow rate. Taken together, these features can result in overall energy savings of up to 30%.

For more information

Contact us